August 2019

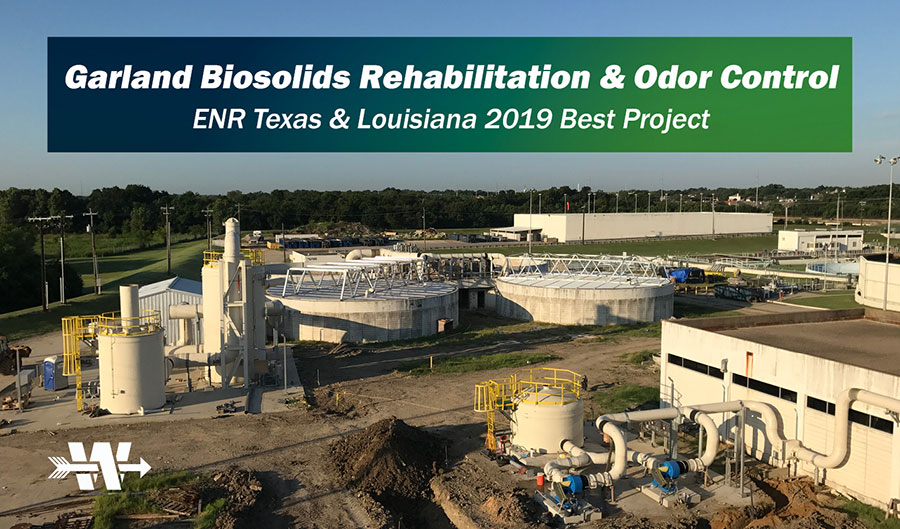

Garland Biosolids Rehabilitation and Odor Control Project named best water/environment project by ENR Texas & Louisiana

GARLAND, TEXAS - The Garland Biosolids Rehabilitation and Odor Control project was named a 2019 Best Regional Project by Engineering News-Record Texas & Louisiana. The award recognizes the Archer Western project as the best water/environment project in the region.

A large focus of the project was to install a new odor control system, sludge thickening rotary drums and dewatering facilities for the City of Garland at its Rowlett Creek Wastewater Treatment Plant. Four existing anaerobic digesters were also converted to aerated sludge holding tanks and a new cake storage and truck unloading facility was constructed.

The sludge holding tanks were the start of the process. These modifications required the demolition and cleaning of existing tank interiors, the conversion of those tanks into anaerobic digesters, and the installation of three new pumps in the basement. Two new rotary drum thickeners were also installed as a part of the next phase for sludge thickening. All modifications called for an extensive excavation for the replacement of all existing piping, and none of it would be operational without the installation of a new control center and switchgear.

The project team worked 113,710 hours with zero safety incidents. Archer Western held weekly meetings to ensure that all employees were empowered to do their job in the safest way possible at the Rowlett Creek WWTP. In these meetings, leadership discussed specific hazards with the crew to increase awareness and identify preventative measures early on.

One of the unique areas of construction was the installation of the centrifuge and conveyor systems. Because of the large amount of equipment in a small footprint, this installation required extensive planning from field staff and careful coordination with the foreman and crews. Teams performed multiple quality checks to ensure the proper installation of the centrifuge and conveyor systems. This involved proving clearance requirements and meeting installation requirements for the centrifuge and conveyor equipment, while additionally facing field constraints.

This project’s success was crucial to the health of the nearby Trinity River, and its usefulness as a drinking water source for those downstream, including the cities of Garland and Dallas. The improvements to the plant reduced the odor impact to nearby residents and ensured a more reliable water system for Garland and beyond.